Anatomy

From pigs, the entire intestinal tract is used for the production of casings, specifically the small intestines (duodenum, jejunum, ileum), bung (caecum), large intestines (colon ascendens & transversum), after end (colon descendens) and fat end (rectum). From sheep, the small intestines (duodenum, jejunum, ileum) and bung (caecum) are used. The intestinal tract of cattle is also used entirely with the exception of the ileum. Its shape differs too much from the jejunum to produce the classic beef rounds and is therefore removed prior to the cleaning process and destroyed. Beef casings are produced from the weasand (oesophagus), small intestines (duodenum, jejunum) which are processed into beef rounds, bung (caecum), large intestines (colon) which are processed into beef middles, and bladders (Ockerman and Hansen, 2000).

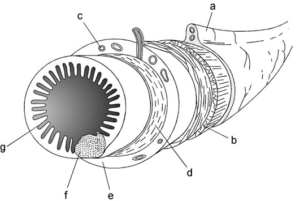

Although there is quite a large variety in shapes and sizes of the intestinal tract between the different species used for the casing production, their basic anatomy and function are remarkably similar. The intestinal wall is composed of four basic layers (Figure 2).

Figure 2: Schematic diagram of sheep small intestine showing mesentery and serosa (a), inner and outer muscle layers (b), submucosal blood vessels (c), muscularis mucosae (d), submucosa (e), lymphoid nodule (Peyer’s patch) (f), and tunica mucosa (villus and crypt layers) (g). The tunica mucosa, the muscularis, the serosa and Peyer’s patches are removed during processing, so the natural casing consists of only the submucosa (e). (Koolmees et al., 2004)

The tunica serosa is the outermost layer covering the intestinal tract. The tunica muscularis consists of two layers of smooth muscle, with an inner layer in a circular and an outer layer in a longitudinal orientation. The tunica submucosa, lying beneath the tunica muscularis, has a microstructure characterized by a network of collagen fibres (type II), elastin and blood vessels of different sizes. For hog and sheep casings, this submucosa is the remaining layer of the intestine after processing and forms the natural sausage casing (Figure 3).

The tunica mucosa is the innermost layer of the intestinal tract and lines the lumen. Embedded in the mucosa lies lymphatic tissue which occurs irregularly along the length of the small intestine as isolated lymphoid nodules (lymphonoduli solitarii), but tend to be most prominent in the ileum. These aggregated lymphoid nodules (lymphonoduli aggregati) are known as Peyer’s Patches and are anatomically located on the convex side of the intestine opposite to the mesenteric attachment.

Taking a sheep casing as an example, figure 4 shows the full thickness of the uncleaned small intestine and Figure 5 shows the tunica submucosa as remaining tissue layer after the cleaning process is finished. A cleaned sheep casing is on average 0.11 mm thick, whereas a cleaned 13 hog casing, also comprising only of the submucosa, is 0.32 mm (Bartenschlager-Blässing 1979; Koolmees and Houben 1997).

A study done by Nishiumi and Sakata (1999) on the histological and biochemical properties of casings found that each casing was composed of numerous sheet-like layers of collagen fibres in a criss-cross arrangement. Differences in gross organisation of the collagen fibres was not observed, but the outer layers of Chinese sheep casings contained more stretched collagen fibres and were packed more densely than Australian sheep casings. These casings had relative fine collagen fibres of loosely packed fibrils. Casings contained approximately 2 % elastin accumulated in blood vessels, without any differences in morphology, localisation and density between samples of different species and origin. Only Japanese hog casings seem to be an exception with lower elastin content. According to Nishiumi and Sakata, the mechanical properties are determined by the size, arrangement of collagen fibres and heat-solubility of collagen present in casings. Differences in the heat-solubility of collagen in casings of various origins may therefore influence usability and palatability of these casings and subsequent studies to tenderize casings will be discussed below.

Processing

The subsequent cleaning process of small intestines can vary between species and geographical location of the cleaning operation. Clear differences exist in how the intestines are pulled from the viscera, being either with a knife, by hand or by machine (Smits and Keizer, 2003). Contrary to hog casings, sheep casings often are fermented prior to the cleaning 14 process. After the manure is stripped from the intestines, sheep casings are placed overnight in a cooled storage during which the mucosa will degrade for easier removal. In general for hog and sheep casings, the manure is stripped out of the small intestines, the mucosa is crushed and removed in various steps and the outer layers, being the tunica muscularis and tunica serosa, are scraped off, leaving the tunica submucosa (Fisher and Schweflinghaus, 1988; Ockerman and Hansen, 2000).

The porcine large intestines are mostly processed into hog chitterlings and fat ends by hand. All layers remain identifiable, whereas it depends on the operation if the mucosa is (partially) removed (Schweigmann and Seeger, 1988; Ockerman and Hansen, 2000). In contrast to the extensive processing of hog and sheep’s small intestines into casings, beef casings retain all original layers after cleaning (Botka-Petrak et al., 2001). A pilot study on the histology of beef casings (Koolmees, 1998) indicated that although most of the tunica mucosa is removed from the small intestines, the tunica muscularis and serosa can be clearly identified and that Peyer’s Patches also remain present.

In order to determine whether a difference existed in cleaning efficacy between manual and mechanical processing techniques, a comparative histological study was done by Koolmees et al. (2004) using sheep casings. Results showed that no significant differences existed between both techniques and that no lymphatic tissue (Peyer’s patches) remained after cleaning.

Mechanical and biochemical properties of casings

An important issue in the quality of casings is their usability for the stuffing process of a great variety of sausages and the consumers’ preferences regarding texture and tenderness. Although these technological aspects are beyond the scope of this thesis, a brief overview is warranted to indicate certain developments.

A study (den Reijer, 1996) done on the toughness of casings in the production of smoked sausages, indicated that many factors not directly related to the casings themselves have a significant influence on the toughness perception. Higher fat content of the sausage meat batter and improved smoking procedures enhance the overall quality.

Various additives, used during the initial curing process of the casings (Bakker et al., 1999) prior to storage in salt, were tested for their influence on the mechanical properties of casings. Combinations of citric acid / Na3-citrate, lactic acid / Na-lactate or phosphates (Na3PO4 / Na2HPO4) and NaCl improved the mechanical properties, with a prevalence for phosphates on the final usability of the casings (Verkleij and Keizer, 2003).

Japanese studies aiming to tenderize hog casings evaluated the effect of lactic acid and pepsin (Sakata et al., 1998) or high-pressure treatment in combination with lactic, acetic or citric acid (Nishiumi et al., 2005), whereas Reichert (1996) studied the effect of a proteolytic fruit enzyme solution on casings after stuffing. A recent study (Nakae et al., 2008) on the influence of trisodium phosphate (TSP) gave a clearer indication than Bakker et al. (1999) that phosphates can reduce the maximum force and breaking strain of casings.

An overall conclusion could be that phosphates are preferred over organic acids and other substances, although a comprehensive study would be required to make a full assessment of the different treatments and their effects on various quality parameters of casings. Such an attempt was made by Schwanz and Schnäckel (2007a; 2007b) who developed an elaborate set-up to test various additives and their influence on the quality of casings. Interestingly, their results also showed that soaking desalinated casings in plain water (45 °C) for around 30 minutes prior to stuffing was sufficient to create an acceptable bite.

Previous topic is History

Next topic is Microbial contamination of casings